STRENGTH

WEIGHT

RANGE

0.050 to 130 Kilograms weight single piece.

CASTING

SIZE

800mm (L) X 800mm (W) X 550mm (H)

SURFACE

FINISH

3.0 TO 6.0 RA. (Depend on Casting Geometry)

DIMENSIONAL

ACCURACY

As per ISO 2768, VDG P690, DIN 1680 Class-II, IS: 11166 Class-II, ISO 8062

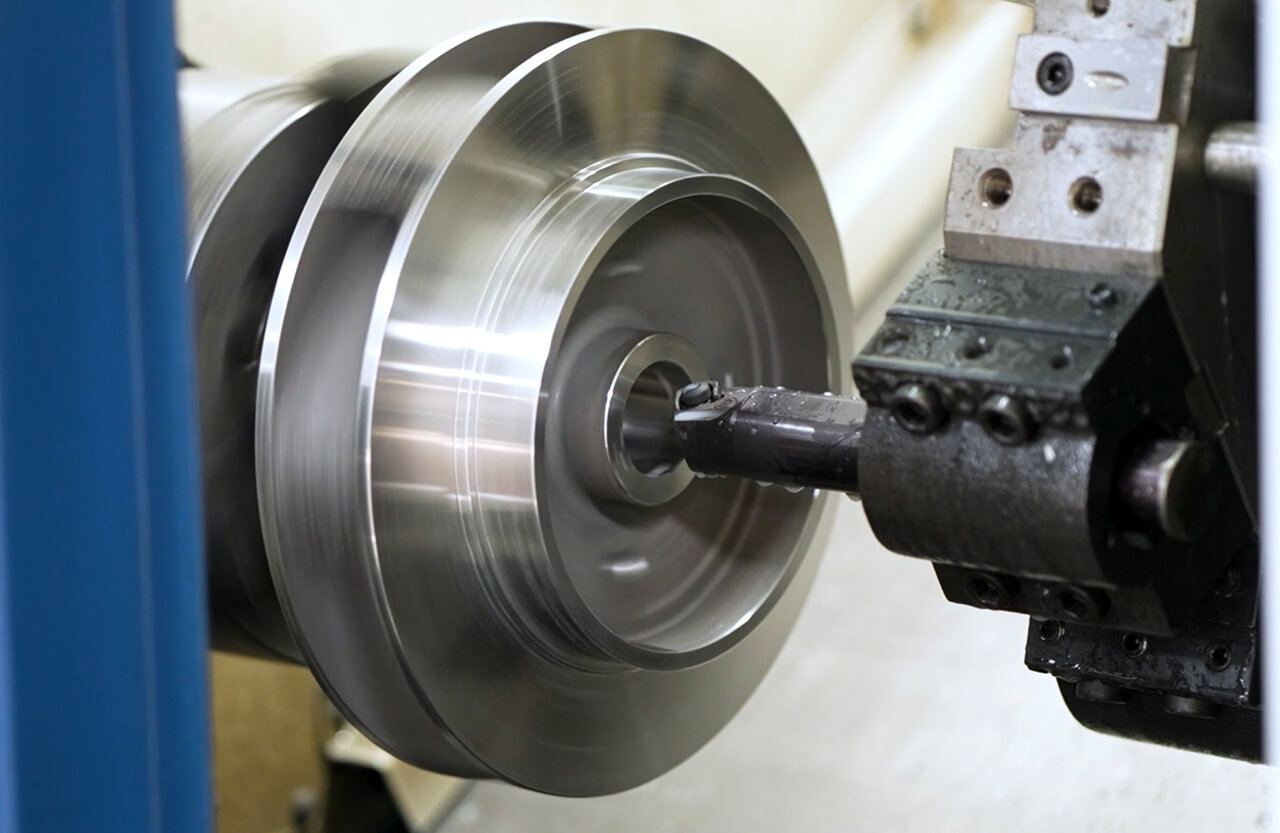

ADVANCED

MACHINERY

Our facility features high-precision CNC & VMC machines and advanced simulation software for accurate production.

CUSTOM

SOLUTIONS

We offer bespoke casting solutions tailored to specific applications and industries.

SIMULATION

Advanced casting simulation software optimizes the process, predicts defects, and ensures consistent quality, reducing lead times.

IN-HOUSE

SERVICES

Our all type of in-house capabilities cover the entire production process, ensuring quality control and efficiency.

One-Stop

Solution

We provide fully finished and ready-to-use parts, saving clients time and effort.

RESEARCH &

DEVELOPMENT

Our R&D team continuously innovates to enhance processes and materials.

Dedicated Project

Manager

Each client gets a dedicated project manager for personalized attention.

GLOBAL SUPPORT

NETWORK

Worldwide representatives ensure seamless communication and consistent service quality.

VALUE ADDES SERVICES

Machining

In-House advanced CNC and VMC machines, we transform raw castings into precise components. Drilling, turning, and threading: every step ensures a perfect fit and finish, ready for any application.

Polishing

With Using processes of electropolishing, mirror polishing and many more, we ensure superior surface smoothness, corrosion resistance and enhanced metallurgical properties for each casting.

Surface Plating

Offering specialized Electroplating, Electroless Nickel Plating, and Anodizing processes, we provide robust, corrosion-resistant finishes, ensuring longevity and aesthetic brilliance for our cast components.